Farm visit – Grower pigs thrive in large groups

Large pens for growers and finishers – that is one of the key features for grower pigs to thrive. With plenty of space to run around and plenty of feed to consume, a German farm is achieving a grower ADG of 480 g and 1% mortality.

The moment farm manager Jonas Zacharias rattles with a bucket, the piglets below him realise what is about to happen. What follows is a nervous gathering of pink snouts. A few scoops of hay pellets disappear into an orange vertical tube, which is hanging from the ceiling. As soon as the growers touch it, the object swings from right to left, with pellets falling through side holes at the bottom.

“For al the pens, we made them ourselves,” says Zacharias with a smile. “We have tried to find something similar in the market but nobody seems to manufacture something like this. We needed them to hang on a chain so that we can adjust them in height. As piglets grow, at some point, they can reach it too easily, so then it wouldn’t be much of a challenge for them.”

Unusually large weaner pens

The toy dispensers are hanging in the middle of the large weaner pens at a modern farrow-to-wean farm with 1,800 sows, located near Dorsten in North Rhine Westphalia, Germany. The owners asked not to publish the farm’s name. The weaner pens measure 22.5 m2 (5 m x 4.5 m) and house about 60 grower pigs each. Most farms in Germany keep their growers in substantially narrower pens – for fewer piglets – Zacharias says.

Yet when the farm strongly expanded in size in 2012-2013, the owners chose to go for “large.” It had been difficult enough to obtain permits, so when these came through the owners opted for two pig houses measuring 50×100 m each, with wide alleys and plenty of light. In the grower house, the size facilitated large pen sizes.

All in all, 18 rooms offering accommodation for 8,000 grower pigs. Zacharias, who started working for the farm when the new buildings were about to be built, praises the large pens, saying, “One can easily overview the pens, it is not too difficult to catch the pigs, we have fewer surfaces to clean and there is plenty of space to have three persons in the pen, as well.”

Feeder type

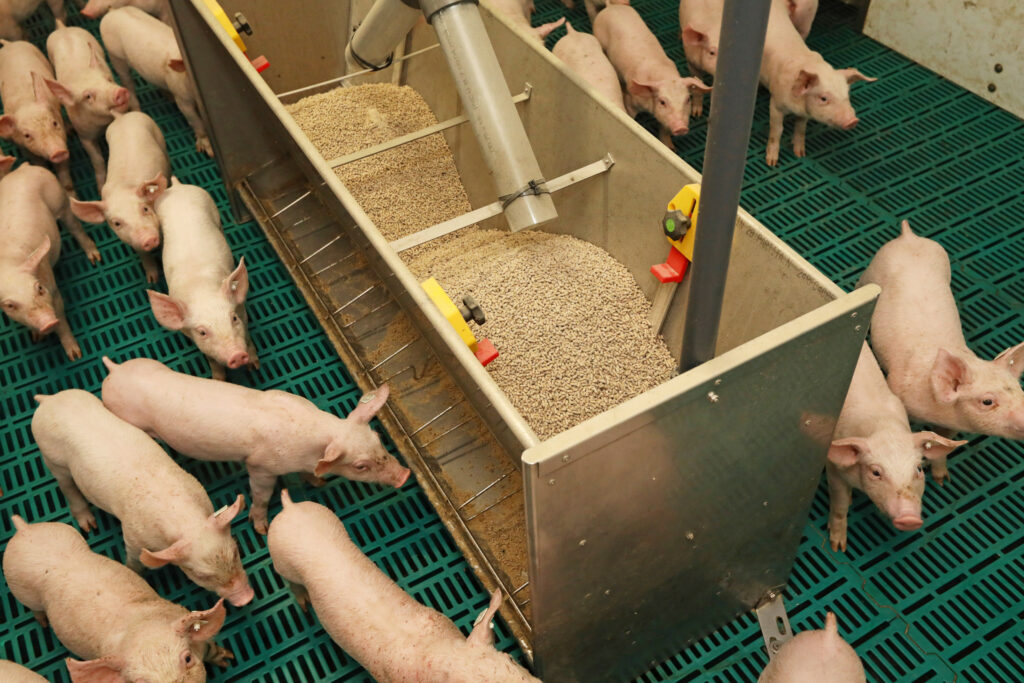

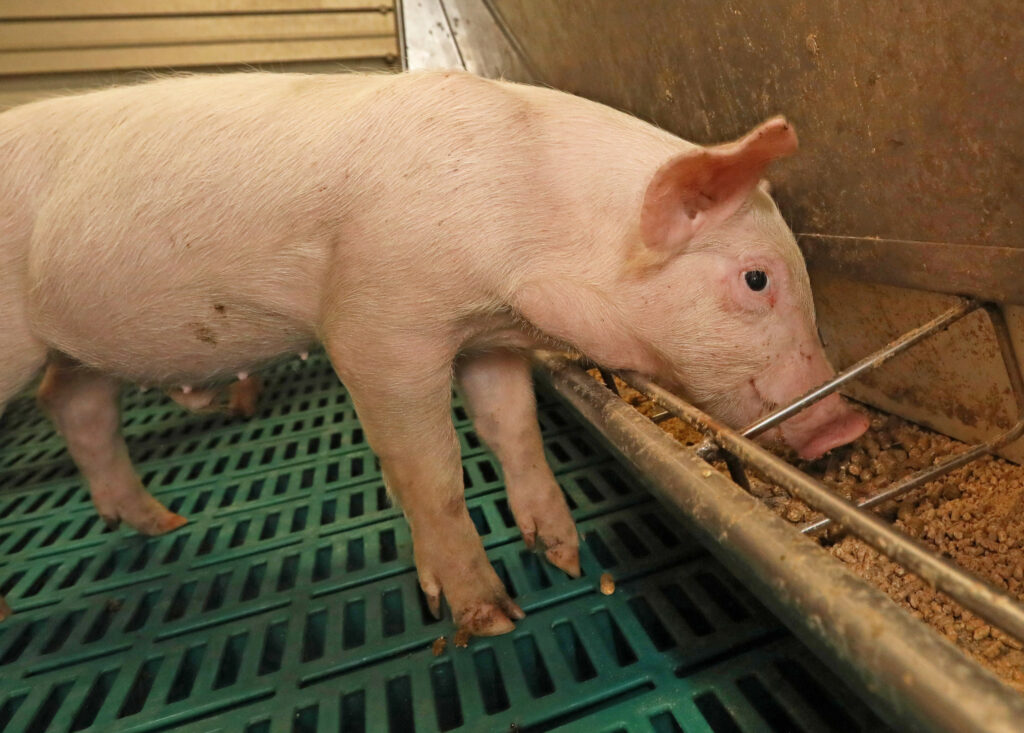

Right in the middle of the pens are double-sided stainless steel dry feeding units with 16 eating places, 8 on each side. These were placed during a very recent renovation in 2024. It has taken the farm a large part of the decade to figure out what type of feeder would be ideal in large-sized pens. Zacharias says, “Initially we have tried to opt for feeding systems mixing feed and water in the trough. We often needed more than 1 unit per pen, though, which was rather expensive if you keep in mind it had to happen throughout the farm.”

He continues, “We have also looked at an affordable steel feeder from a Polish manufacturer, but we eventually ended up going for dry feeders by Verba from the Netherlands.” The dispensers have been equipped with a sensor. Should the trough be empty, it is refilled every 2 hours.

From mash feed to pellets

The switch to the dry feeding units brought about a switch from mash feed to pellets. Probably that was when all the stars aligned, Zacharias assumes, the first quarter of 2025 yielded the highest-ever observed growth on the farm. From January to March 2025, the animals grew on average 480 g/day with a 1% mortality rate, between weaning at 28 days (7 kg) and transport to the finishing barns at 80 days (about 30 kg). “The previous record was at about 435 g,” Zacharias recalls. “Normally, we would achieve about 420 to 430 g/day per quarter.”

Interestingly, the farm also works with two “infirmaries,” where the smallest grower pigs of each week group are being kept for two weeks. These animals are pampered with a heated floor and a sophisticated feeding unit. The result: after two weeks, the vast majority has caught up and can go back into their age groups without any problem.

4 different diets

During their stay in the weaner house, the piglets receive 4 different types of feed. Initially, they receive a prestarter – which is already supplied to them while they are still with the sow. This is supplied by Koudijs Animal Nutrition, part of De Heus.

In the subsequent weeks, the animals switch to 3 different grower diets, the last one of which is almost identical to finisher feed. These feeds are supplied by Raiffeisen Hohemark Hamaland, a feed producer in the nearby town.

Larger operation

The farm site, which is concealed from the main road by a dense forest, is part of a larger operation, which also includes a 230-sow multiplication site at a short distance away. The entire operation works with the German animal welfare scheme Initiative Tierwohl.

In terms of sow welfare, the farm will still have some decisions to make in the near future. As from 2036, free farrowing will be mandatory in Germany; in addition, freedom in the mating house will also become mandatory from 2029 onwards. The free farrowing will force the farm to either build more pig houses or bring down the number of sows – but the real problem Zacharias foresees in the mating area. Perhaps allowing the just-weaned sows to go outside could meet the spacing requirements. “However, sows around ovulation can behave unpredictably, with mounting and biting. That is not animal welfare, in my view. It could be a catastrophe.”

Apart from the vertical toy-feeders with the growers, there are various other welfare initiatives in the grower building, like chewing bars, other hanging toys, and keeping the male pigs intact – as the farm separates male pigs from female pigs. That has been organised further downstream, as well. When the piglets reach 30 kg, they are shipped to four finishing farms of other owners, each of which also works with entire male pigs.

The farm portrayed in this article is always interested to acquire new staff. Interested readers could contact the editorial desk of Pig Progress at info@pigprogress.net.