New research into how to improve fermentation

The use of liquid feeding in pigs comes with benefits, but also with question marks. In order to even better understand the process inside liquid feed, a collaborative French consortium aims to uncover fermentation processes in the feed. In this article, the first results are discussed.

By Marjorie Dujardin, Bretagne-Sud University and Yannig Le Treut, Lallemand Animal Nutrition

Liquid feeding is given to 60-70% of pigs in Brittany, France’s leading pig production area. This could explain the local authorities’ involvement in a collaborative research project dedicated to this particular type of feed.

©

This three-year project, named Probiomas, gathers various industry and academia partners and its main objective is a better understanding of liquid feed fermentation and the influence of different factors, in order to optimise the quality of liquid feeding; see box ‘An innovative project’. Probiomas is part of French agrofood cluster Valorial, and its ultimate goal is to contribute to improve food hygiene and quality and help maintain value in the pig industry.

©

The pilot plant

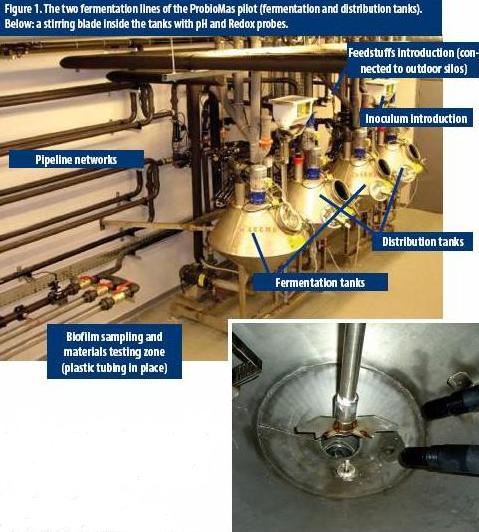

A pilot liquid feeding plant was developed by French feeding plant manufacturer Acemo for the project (see Figure 1). This pilot has two independent fermentation lines, enabling to study the effects of any parameter (temperature, type of grain, particle size, use of an inoculum, etc.). Several probes and sampling windows allow the monitoring and recording of many parameters during the fermentation process: pH, redox potential, temperature, pressure, sampling for microbiological, chemical or nutritional analysis, etc.

©

Each fermentation line is composed of a fermentation and a distribution tank, and a pipeline network that mimics the effects of the distribution pipeline at farm level: feed fermentation and biofilm occur in the pipeline and influence the quality of the feed. Removable sections of this pipeline also enable to study the biofilm attached to the pipe surface and evaluate the impact of different materials on the biofilm (cells viability staining in epifluorescent microscopy).

©

The temperature effect

One of the first trials performed with Probiomas aimed at studying the effect of the feed temperature upon fermentation. A mixture of 1/3 ground wheat and 2/3 water, without additional fermentation aid, was fermented simultaneously in the two lines at 20˚C and 25°C, for up to 48 hours. As a result, it appeared that a +5°C difference in temperature has a significant impact on the fermentation kinetics (Figure 2). The onset of fermentation (defined as a drop of pH) starts ten hours earlier at 25°C, and pH 4 is attained 14 hours earlier, leaving less time for the potentially pathogenic bacteria present in the grains to develop.

©

©

©

The benefits of pre-fermentation

Another lesson learnt from the Probiomas project so far is the effect of using an inoculum to kick-start the

fermentation. When ground wheat and water were fermented at 25°C, without inoculation, fermentation starts slowly: the pH starts to drop after twelve hours, and pH 4 is attained after 20 hours. At this time, a second round of fermentation is started with 20% inoculum from the first batch: initial feed pH is lower, and acidification starts immediately. The level pH 4 is attained after only six hours and the final feed pH after 24 hours is lower than in the first round. A third fermentation round (always with a 20% inoculum) shows similar acidification kinetic (pH 4 attained after six hours, final pH 3.5).

fermentation. When ground wheat and water were fermented at 25°C, without inoculation, fermentation starts slowly: the pH starts to drop after twelve hours, and pH 4 is attained after 20 hours. At this time, a second round of fermentation is started with 20% inoculum from the first batch: initial feed pH is lower, and acidification starts immediately. The level pH 4 is attained after only six hours and the final feed pH after 24 hours is lower than in the first round. A third fermentation round (always with a 20% inoculum) shows similar acidification kinetic (pH 4 attained after six hours, final pH 3.5).

©

©

Microbiological analyses (Figure 3) show a correlation between acidification kinetics and the feed lactic acid flora. Total microbial numeration shows that the feed microflora is essentially composed of these lactic acid bacteria.

©

When looking at total coliform population and more specifically E. coli, the benefits of an inoculum are clear: in the first fermentation, the slow acidification of the feed allows coliforms to grow in the feed: E. coli population has increased 100-fold within 24 hours. During the second and third rounds of fermentation, coliform populations keep decreasing. At the end of the third batch, the total coliforms population is lower than the initial feed contamination, while E. coli remains at a steady level, similar to initial concentration (1.5 x 102 CFU/g).

©

Outlook

The preliminary work with the Probiomas pilot has confirmed that fermentation is a complex process, involving many parameters, not always easy to control, such as temperature, time, microbial populations present in the feed, and their physiological state (importance of a pre-fermented inoculum). It is also conditioned by the type of nutriments, type of cereals or the particles size, etc. other parameters that will be studied. Further on-going studies also aim at evaluating the effects of a controlled fermentation with P. acidilactici MA18/5M

inoculation.

inoculation.

©

©

An innovative project© ProBioMaS (short for Probiotique + Biofilm + Machine à Soupe) is a consortium of companies and academia with complementary expertise, including probiotic producer Lallemand Animal Nutrition, the animal feed premixes company Inzo°, French liquid feeding plant manufacturer Acemo, animal health and hygiene expert Noé, and Limat B research laboratory from Bretagne-Sud University. The project is partially funded by regional and national funds. The goal of this unique project is to better understand the fermentation process, define precisely the impact of various parameters (temperature, feed composition and particle size, pre-fermentation, inoculation with specific lactic acid bacteria, etc.) on the process and finally on the feed nutritional and sanitary quality. This should help optimise both the preparation of liquid feed and the fermentation process, and finally draw some practical guidelines for pig producers. One of the key criteria, besides feed fermentation, will be the establishment and maintenance of a positive biofilm on the inner surfaces of the tanks and pipelines. |

©

Source: Pig Progress Volume 25 nr©6

Join 18,000+ subscribers

Subscribe to our newsletter to stay updated about all the need-to-know content in the pigsector, three times a week. Beheer

Beheer

WP Admin

WP Admin  Bewerk bericht

Bewerk bericht