Farm visit: Hungary welcomes multistorey sow house

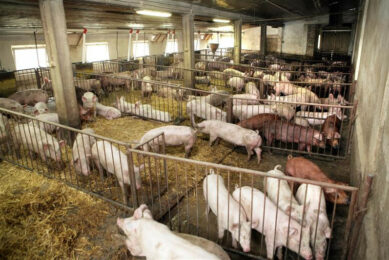

Suzanne and Jos Janssen own livestock trading company Hunland in Hungary. In June, the company opened a new multi-storey pig house for 4,080 sows. The piglets will go to finishing pig farms in their own integration. The owners call it a pig house like no other.

The multistorey sow farm Felsőbabád went into production in July 2023. The farm offers housing ot 4,080 sows, 875 gilts, and 18,380 piglets. The building is an impressive structure in the Hungarian countryside, located at less than an hour’s drive from the capital Budapest. It is in the middle of the agricultural countryside with plenty of corn and grain right next to the facility.

Owners Suzanne and Jos Janssen bought the site in 2020. At the time, the farm had capacity for 800 sows and finishing pigs. “A year later we decided to build new,” they explain. “We only had to amend the environmental permit. That went quite smoothly.”

Construction of the complex

Construction of the complex commenced in April 2022, when the weighing bridge was installed, followed by the asphalting of the farm roads. That way, the builders of Van Genugten Agri could ensure decent and clean accessibility to the construction. The total farm site measures 20,500 m2, consisting of new construction (17,476 m2), a manure storage pit (1,017 m2), and existing buildings (2,011 m2). Construction continued at a rapid pace, as the farm’s official opening took place in June 2023.

Welcome construction

In Western Europe, a pig house of this size may be frowned upon, but in Central Europe it is welcomed. In Hungary, a lot of money is put into renewing, strengthening and modernising agriculture. Hunland received a € 5.26 million grant for the construction of the facility. Of that amount, 82.5% comes from the EU, the rest is being co-financed by the Hungarian authorities. Total investments for the farm amounted to € 20 million.

Investments needed

Investments in an own breeding facility were needed, as Suzanne and Jos Janssen saw market conditions had gradually been changing. As a trading company Hunland has been purchasing 1 million pigs per year, mainly from Germany and Denmark. They say, “Due to transport restrictions, piglet imports are becoming increasingly difficult. Moreover, piglets are scarce with some regularity and their price is high. We have our integration here in Hungary with 60,000 finishing piglets. We would like to expand this integration to 100,000, but preferably to 150,000 finishing pig places. We produce the feed ourselves.”

Construction of expensive storey stable

That all led to the construction of a farm of which the total floor area exceeds the size of the construction site, as the farm building’s surface amounts to 27,000 m2. That is because it is a multistorey pig house. The piglet area was constructed on top of the lactation and insemination sections. Sows are being released into group housing 1 month after insemination. Gestation as well as the area for GP sows takes place in an adjacent building, without an extra floor.

The choice of an added floor was prompted by regulations. Of the land area of 73,675 m2, a maximum of 30% could be built on. Even though building a high-rise building is extra expensive, the owners and constructors see the advantages: short walking distances and a having a compact pig house, saving energy.

The house is compact, with everything being packed close together. Ceilings are 3m or more and plenty of daylight is coming in. The piglet delivery area is located between the lactation house and the sow house. Right next to that is the carcass storage as well as an oven for cremating dead animals. A ramp has been made to get piglets onto the upper floor and back down again, with midway up being the delivery room. The addition of a second floor is what made the design extra complex. In total 270 rectangular concrete pillars had to be constructed to support it.

Energy, hygiene and safety

As there is no connection to the natural gas network, energy needed for heating is extracted from outgoing stall air. Heat recovered from the sows in the gestation house is used to preheat the incoming air for the farrowing and piglet house to around 15°C in autumn and winter. The heat produced by all animals in the multistorey house is used for both space and floor heating with the weaners and lactating sows. To that end, there are five heat pumps in the technical room as well as a heat exchanger.

Pad cooling – a method which requires little energy – is used in summer to treat incoming warm air, whilst also slowing down its speed. The farm opted for ceiling ventilation in all pig houses, as it leads to the most optimal air distribution for the animals. In addition, fresh air is being brought to the sows via a fresh-nose system.

The piglet house

Technology and practicality can be found in the smallest details. Just an example: boot cleaners have been integrated inside the floor. In addition, the soaking installation in the piglet house is a nice feature. The all-plastic technology, known from horticulture, include nozzles that can be replaced with 1 click. An anti-drip system prevents dripping. The soaking installation has a separate 50 mm-thick supply pipe. The pipe has an electric valve with a timer, which allows the soaking installation to be switched on and off at any time. The piglet house is also designed to be cleaned by robot.

Construction company Van Genugten Agri also anticipated for the installation of air scrubbers. Air emission occurs centrally throughout the farm. That happens via well-insulated and sealed ducts. Central air extraction is ideal for heat recovery.

Business strategy

Hunland uses a number of contract farmers for the finishing purposes, mostly families with their own pig houses with a 500 to 1,500 finisher pig capacity. Jos Janssen says, “There are also former state farms among them with 5,000 fattening pig places with staff. On all farms, we would like want to board healthy piglets, from a single source.” In that context he refers to Actinobacillus pleuropneumoniae (App), PRRS and Mycoplasma hyopneumoniae (M. hyo).

Janssen does not dismiss the idea to expand the farm at a later stage. “If we get the management right here, I like to put up a few more sow stalls like this. Potential farm managers have already come forward from Denmark and the Netherlands. We can accommodate them as well. In front of the barn is the office with hygiene locker, along with five flats with ten beds. Still, the intention is to work only with Hungarians. Language is important as you have to understand each other well as colleagues.”

Expansion into slaughter and processing does not have top priority, explains Janssen. “In Hungary, there is more than enough slaughter capacity, but the sector is not that agile. Pig selling prices are fine though, with € 0.25 being paid more than in Western Europe. That is because slaughterhouses are understaffed. Meat is mostly sold domestically. Investing in slaughter capacity myself is only an option if really necessary.”

Risk of ASF

Even though Hungary managed to eradicate PRRS, the country does harbour another health risk: African Swine Fever. Jos Janssen says, “We have to be alert to that. If pigs test positive for PRRS or ASF, a farm is closed down, with the government only compensating the animals. The consequential damage due to empty pig houses would be at our own expense, costing a lot of money.”