Fighting the inodorous, invisible killer

Pigs are highly sensitive to Mycotoxins and economic losses are consequently very important. Even if diagnosis is difficult, preventive solutions do exist to avoid mycotoxicosis. Using modified clay is one of these solutions.

By Erwan Le Bras, Olmix field engineer, France

Mycotoxins are a group of various secondary metabolites produced by fungi that occur in raw materials worldwide. Contamination is often unavoidable due to certain environmental conditions (such as humidity, heat, insects, etc). When animals consume the contaminated feed, they may develop ‘mycotoxicosis’, a term that was first used by Forgacs and Carll in 1955.

Pig sensitivity

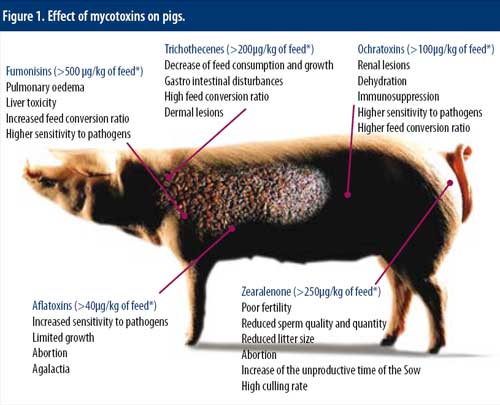

Pigs are quite sensitive to mycotoxins. Effects of high levels of Mycotoxins are well known (for example vomiting and abortion) but what we mainly see in the field are the effects of chronic exposure to low levels of mycotoxins: reduced feed intake, lower fertility rates, and vet costs increasing; symptoms that are usually not directly linked to mycotoxicosis.

For example, for each ppm of the mycotoxin deoxyivalenol (DON) ingested by the pig, its consumption and growth will decrease by 5%. 1 ppm of fumonisin will decrease the growth by 8%. Diagnosis is difficult, but it is clear that mycotoxins are ‘silent, inodorous and invisible killers’.

As acute mycotoxicosis is easy to diagnose (reduced in feed intake and growth, abortions), chronic intoxication at low contamination levels is more difficult to identify (limited consumption, recurrent pathology, infertility, limited growth, vaccination failure). In this case, clinical signs may be associated with bacterial diseases instead of mycotoxicosis.

Sampling methods

Visual assessment of the feed is not sufficient; fungi may no longer be present but toxins still remain. A problem with mycotoxicosis is that it appears at very low contamination levels and the combination of several mycotoxins has a drastic impact on economic losses. Moulds tend to develop in isolated pockets (‘hot spots’) in the stored commodities and, after having been consumed, there is little evidence of their existence. Accurate mycotoxins concentration in the feed is difficult to assess due to this heterogeneous concentration. The precision depends on the sampling method, sample preparation and analysis method. Sampling is usually the largest source of variability associated with the mycotoxin test procedure. A reliable, sensitive and quantitative analysis (liquid chromatography coupled with mass spectrometry) is recommended to assess precisely the contamination level and to adapt the treatment to be implemented.

Different prevention methods

Because mycotoxins are a great risk to animals, much attention has to be given to prevention even if the knowledge of best practices is not sufficient to make the hazard avoidable. Prevention of mycotoxin formation through good agricultural practices in the field is important in the feed industry. Factors favourable to the development of fungi in the field:

• Hot and wet climate during the year

• Previous cultural crops

• Non ploughing of harvest residues

• Use of varieties sensitive to fungi

• Long interval of time between harvestand drying of raw materials

The addition of several of these risk factors may lead to contamination. Secondly, the integration of a selection of genetic and molecular crops on disease resistance has been investigated for breeders to limit economic losses in the field. However, disease resistance is relative and hybrids may vary in reaction to a disease between reactions that are resistant and susceptible. The most common methods of mycotoxin prevention are the use of mould inhibitors. They prevent the Development of moulds in stored commodity.

However, if mycotoxins were already formed in the field, the feedstuff will stay contaminated and keep its detrimental effects on animal health and production. In addition, the use of a mould inhibitor on the field, if applied during fungi development, may produce mycotoxins due to the stress that it generates.

Grains treatment

Mycotoxins are chemically stable during all manufacturing processes such as temperature (fumonisin is resistant up to 200°C) and pelleting. Chemical treatments are not realistic in industrial situations, Mycotoxins resist storage and mould inhibitors may lead to the production of mycotoxins. So, the difficulty in removing a mycotoxin is so high that the best solution to control mycotoxicosis is prevention through the feed with the addition of a mycotoxins inactivator to avoid mycotoxicosis being the limiting factor of the pigs’ performances. Due to the fact that climate is uncontrollable, a mycotoxins inactivator which is largely efficient and reliable at low dosages, is the best solution either in preventive or in curative situations.

Intercalated clay for more adsorption

Over the past years, some research has been done on mycotoxins absorption. A major breakthrough in the development of mycotoxin inactivators has been the invention of pillared layered clay in which the interlayer space has been enlarged on a nanometre scale, creating a very effective trap for various mycotoxins. Thanks to the combination of this clay with seaweed extracts, yeast cell walls and diatomaceous earth in its formulation, the final product is introduced in animal feed to prevent contamination of different classes of toxins (aflatoxins, ochratoxin, trichothecenes, zearalenone, fumonisin). This intercalated clay (Amadeite, Olmix) has been tested in in vitro and in vivo conditions to get an overview of the efficacy that can be expected on the farms. In vitro trial was implemented in the Netherlands, with the most reliable simulator of the pig gastro-intestinal tract: TIM- 1 from TNO (the Netherlands). The clay was tested on a standard pig feed contaminated with 1 ppm of DON and 2 ppm of fumonisin B1 in the conditions of the test. It was shown that the clay was able to absorb 40% of the DON and up to 60% of the fumonisin with an incorporation rate of 1 kg/tonne of feed. There was no significant impact on nutrient availability (vitamins, nitrogen and carbohydrates).

Improved fertility

A study carried out in 2007 by Professor Bui Huy Nhu Phuc from the University of Agriculture and Forestry in Ho Chi Minh City, Vietnam confirmed the efficacy of the final product formulation on multicontaminated pig feed. Twenty gilts received a multicontaminated feed for ten months and weaning of the piglets occurred at 22 days of life. Reproduction and production performances of gilts were measured throughout the trial. Two levels of inclusion were tested: 0 (control) and 0.5 kg of the clay per tonne of feed to suit with an average contamination level (125 ppb of T-2 toxin, 125 ppb of zearalenone, 510 ppb of fumonisins B and 50 ppb of DON). The incorporation of this mycotoxins inactivator improved pregnancy rates (+50%) and reduced the unproductive time of the gilts (younger age at first farrowing and interval first oestrus-farrowing reduced by nine days with the use of the clay, see Table 1). An improved litter size (+21%) was observed together with a higher piglet birth weight (+13%). In addition, the number of weaned piglets/ litter was increased (+4 piglets/ sow/ year). Furthermore, sow feed intake during lactation was higher (+410 g/day) in the treated group, which induces that the lack of palatability caused by fumonisin, deoxynivalenol and T2-toxin is reduced.