Roxell unveils new feed management systems for pigs

Roxell has launched 2 innovative products designed to optimise feed management in pig farming: the next-generation Discaflex feed transport system and iQon Multifast, an upgraded smart batch feeding system. These advancements underline Roxell’s commitment to providing flexible, precise, and user-friendly solutions for farms of all sizes.

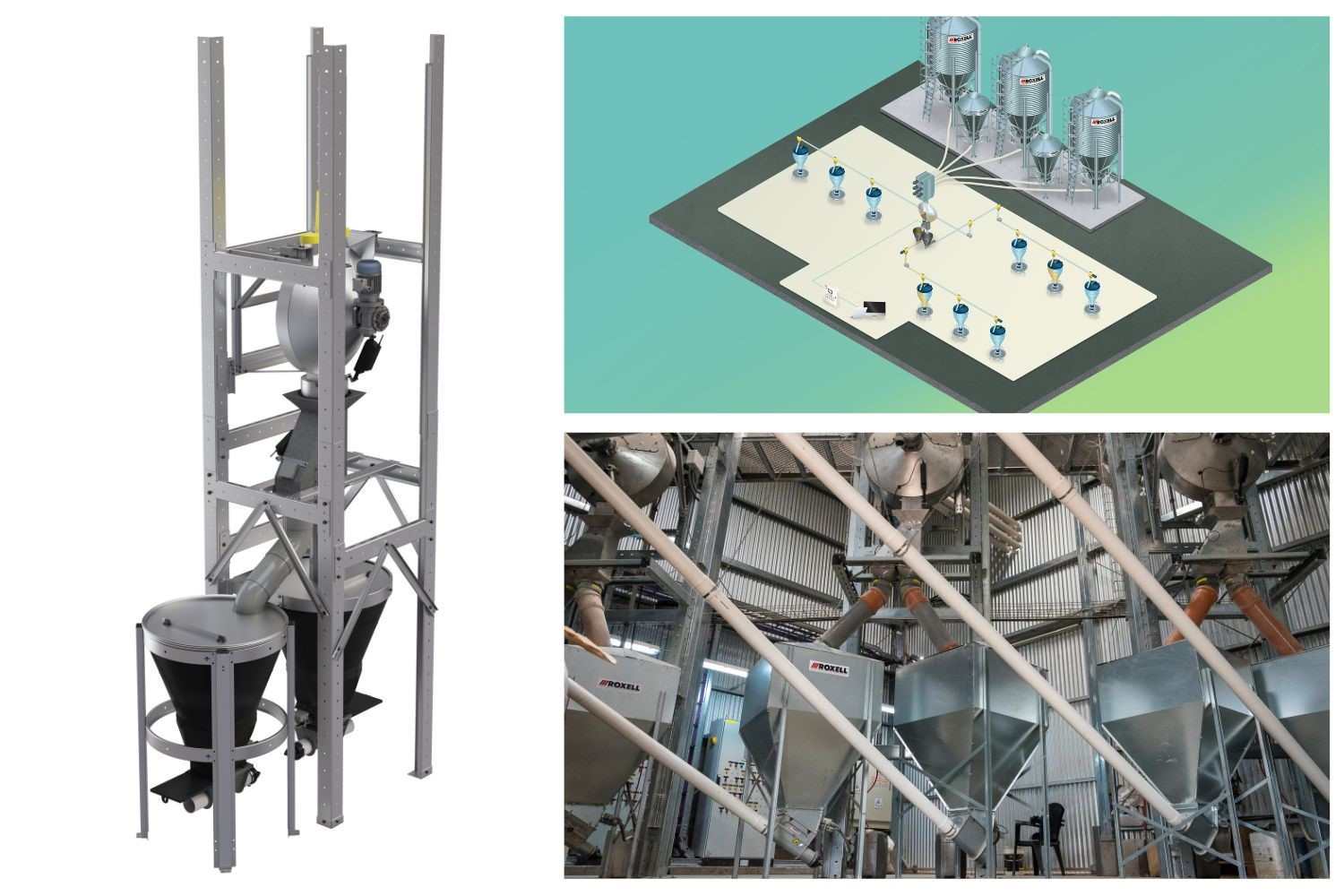

Discaflex: precise feeding, for farms big and small

The new Discaflex feed transport system redefines precision and adaptability in feed distribution. Moving beyond a one-size-fits-all approach, Discaflex is engineered to provide tailored feed distribution solutions that cater to the unique requirements of modern pig farming operations, from small family farms to large commercial enterprises.

A key innovation is the introduction of 3 distinct drive units, allowing customers to select the ideal feed transport capacity for their specific needs:

- A drive unit ideal for smaller farms provides a capacity of 800 kg/h for circuit lengths up to 200 m. Its design prioritises ease of maintenance and installation, avoiding unnecessary costs for smaller-scale operations.

- Meeting the demands of installations requiring higher capacity, another drive unit offers 1400 kg/h in circuit lengths up to 300 m.

- For the longest circuits there is an option that delivers 1400 kg/h at a circuit length of up to 400 m, ensuring extensive reach, shorter refill times, and smooth feed delivery.

Discaflex also boasts enhanced flexibility in feed management. A single adjustment piece at the intake boot now allows the system to easily handle both meal and pellet feed, simplifying transitions and improving flow.

Roxell also offers new motorised intake boots for direct filling under a feed bin, minimising blockages and reducing wear. A budget-friendly non-motorised option is also available.

Durability and smooth operation are at the core of the Discaflex design. The system features smart motor overload protection, extending the motor’s lifespan and improving reliability. Another significant development is the use of 60 mm diameter tubes, available in both galvanised and stainless steel. This improvement introduces new compatible components, including a new corner wheel and updated manual and automatic outlets. A new chain with bigger oval disks (43-45 mm) maintains Roxell’s renowned chain strength while preventing chain torsion for smoother operation and an extended lifespan. Importantly, this new chain and disc can be retrofitted into existing 56 mm diameter systems, offering a cost-efficient upgrade path.

“This approach for every type of configuration ensures that pig farmers invest in a system that perfectly aligns with their specific requirements, maximising efficiency and minimising unnecessary costs,” explains Ludo Bosschaerts, product manager at Roxell. “Whether it’s a small family farm or a large commercial operation, the upgraded Discaflex delivers unparalleled performance and value.”

iQon Multifast: smart mixing, precise feed delivery

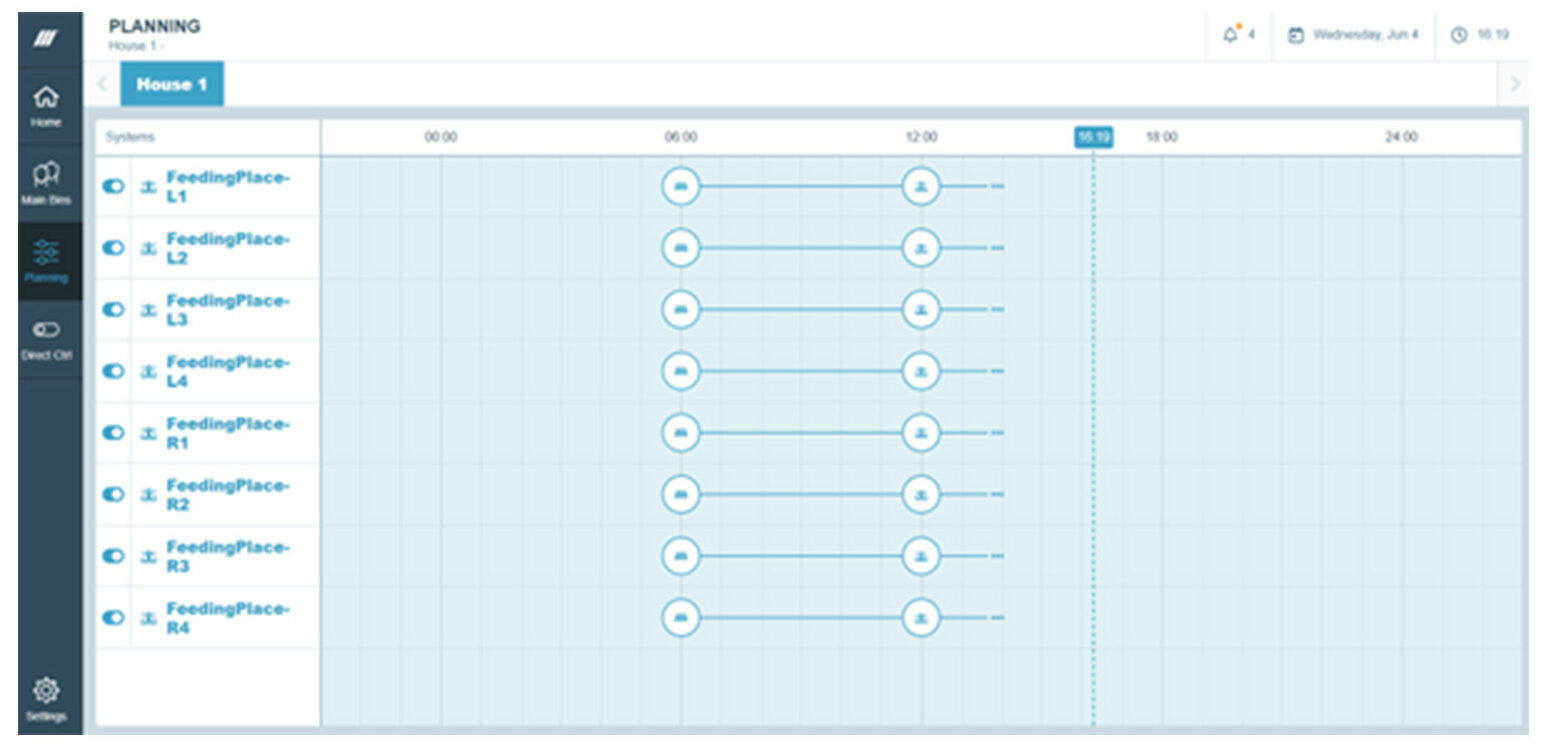

Roxell introduces iQon Multifast, the upgraded version of its advanced batch feeding system. As of June 2025, Multifast, Roxell’s batch feeding system combined with a weigher/mixer, will be controlled by the smart iQon control platform, significantly enhancing user-friendliness and precision in feed management for pig houses.

In its initial phase, iQon will control both 100 L and 200 L weighers/mixers, delivering each batch via a single hopper to the desired feeding location, exclusively using flex-augers for transport. Future phases will expand control to include a switch valve with two hoppers, a vibrating motor, and flex-auger rotation speed.

The integration of the iQon platform elevates the Multifast batch feeding system to a new level of flexibility and intuitive control. This robust system manages and connects feeding processes from the feed bin to precise delivery to the pigs. iQon Multifast offers advanced feed management capabilities, including:

- accurate reception of the correct quantity of all ingredients,

- selection of various batch sizes,

- free setting of mixing time,

- control over left or right rotation during mixing,

- dosing by weight or time.

iQon Multifast enables smart phase feeding with up to 20 different ingredients. This precise control reduces waste, lowers feed costs per pig, and maintains optimal feed quality. The system’s strength lies in its ability to facilitate gradual transitions between different types of feed, benefiting both feed expenditure and animal welfare. The optimised batch composition and size ensure that the optimal batch can always be delivered based on the group size and age of the animals.

Furthermore, iQon Multifast supports the concept of a feed kitchen, allowing farmers to use self-produced raw materials. This can significantly lower feed costs and enable a highly customised feeding process. Feed composition and quantity can be adjusted at any time to the specific needs of the pigs, resulting in reduced feed costs and a minimised CO² footprint. The system supports control for up to 50 feed curves, with options for step-by-step or gradual batch adjustments, and supports both daily fixed amount delivery and ad libitum feeding.

Designed for durability and user-friendliness, the iQon platform also includes capabilities for remote monitoring and software updates. This leads to faster availability of new features, more efficient service, and reduced downtime. Additionally, the system contributes to the biosecurity of pig farms by minimising the need for on-site visits and by managing all feed transport overhead, outside the farm walls.