Comfortable controlling for pig unit operators

Pig farmers require control systems which offer comfortable and clear support for their service management. With the present update “Service-ModuleExcellent 4PX/4BO“, Weda Dammann & Westerkamp GmbH from Lutten offer pig farmers a new instrument, made available for their animal house management.

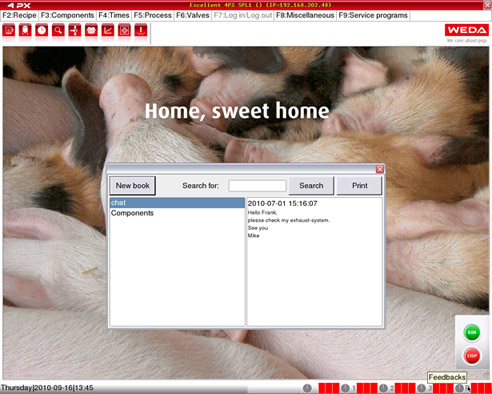

1. Chat

By means of Tool Chat a modern communication platform is made available for the user who will be able to gain relevant information with this. The unit manager will now be able to exchange information with his staff or with Weda’s Service via coupling. In exchange, a chat is now taking place as the information can be looked at and can be answered. The dialogues can be stored in the feeding computer “Exzellent 4PX“, together with date and time.

To supplement the chat, the operator can use this tool for creating personalised or specialised notebooks. With the functions “Copy“ and “Paste“ it is possible to add consumption data which – if required – can be used by the mechanic, the service or by the unit staff. Before their vacation or in case of sickness leave, Service staff can deposit information in the program. The information is permanently callable and will not get lost.

2. Power Consumption

The benefit of the tool Power Consumption lies in the optimisation of so-called power peaks of the current collectors. In everyday life the unit manager can see at a glance which electrical devices were started at a given time and which capacity (in KW) was consumed. This in turn forms the base for the optimisation of his daily schedule to let the engines run one after the other and not at the same time. For example, by starting the motor of the grinder only after feeding, costs can be saved by a more advantageous purchase of power.

Power Consumption offers the user the possibility to enter a respective capacity limit by himself (power consumption in kW over a period of x minutes). If this is exceeded he will receive a warning hint via a window on his screen. Electrical devices which are not connected with the Excellent 4PX system as a standard (milking machines, elevators or grinder motors) can be taken up into the table via a special entry. Motors and electricity consumers will not be controlled or switched off by this, either.

3. The Maintenance Plan

The plan offers the user a complete outline on maintenance work of the available technical devices which has to be carried out and which will be picture in the form of a table. If maintenance work is forthcoming, a report is made. Respective maintenance orders are assorted according to priority always at the top of the table. Only after having set the “tick off” hook, the interval of the maintenance order starts afresh. The user can read from the table at a glance when the next, the last maintenance and the one before the last has to take place, resp. has taken place. The unit manager can enter his maintenance order personally via the free text entry. The tool moreover enables him to enter the maintenance intervals for his complete unit technology. The maintenance intervals are – depending on the device – entered in days or in hours. Possible examples: “Cleaning of the milking machine”, „Oil level of compressors“, “worming treatment of the dog”.

4. Operating Hours Counter

A useful tool is the new application Operating Hours Counter. This is used for the simple, fast and uncomplicated display of the de-facto operating hours of all connected electricity consumers. This is very useful for the correct observance of the maintenance intervals and as a calculation base for the management.

5. Reciprocal Remote Control

The special features of this instrument: the user can have access to a PC or other computers like ventilation computer or climate controller from his feeding computer. Until now it has only been possible to have access from PC to feeding computer. The operation of E-mail programs or internet access can now take place problem-free and fast. In units with raised hygiene standard this means a considerable gain of time; – alone the frequently laborious procedure of showering is not necessary any more. There is moreover the possibility of telecontrolling animal houses which are situated far outside the central building.

6. “Plotting” Graphs

By means of this all available measured values of the computer can be arbitrarily displayed on the screen surface. This enables the user to adapt important management parameters to his specific conditions, e.g., the display of the administered feed amount depending on the inside and outside temperature. This way, the farmer can see at a glance that the continuity of the feeding behaviour changes under rising temperatures. With the aid of the tool the operator can change the room climate and can this way carry out adaptations.

The Advantages:

• Great simplification for the management and an increase of total efficiency

• Holistic use of the service modules possible

• Cost management becomes easier

• Production processes are easier to structure

• Optimization of communication by means of networking

• Simplification of complex tasks due to more transparency

• Service modules for the a minimization of costs

• Animal management is further optimized (competitive advantage)

• Much better view of animal health

• Time saving by optimization

• Compatibility with other computers simplifies technical processes

For more info: Weda