Particle size control helps pig stomach health

Fine particle size feed can impact many things in pigs, such as growth performance, welfare or mortality. A team of Danish experts have recently been working on developing a monitoring tool in feed factories to control particle sizes.

Finding the right particle size for pig feed is a matter of balance. On the one hand, very fine particles enable optimal nutrient use and will enhance animal performance. Very fine particles, on the other hand, can also negatively affect gut health because they cause higher incidences of stomach ulcers in pigs (see also Box). To reduce or even avoid stomach ulcers, the science suggests to include more rough particles. However, this can go at the expense of a lower feed efficiency.

All in all, a fine balance. And that is just the beginning. Because when the balance has been found, it is also vital to maintain it. Doing so goes beyond just making sure that the settings of the feed mill are correct, as the feed-making process requires constant monitoring. Changes in particle size can occur to the detriment of the mills, for instance. Or changes in the dry matter content of grains and dietary protein sources could influence the feed-making process.

In the Danish pig industry, the topic of gastric ulcers — and its relation to particle size — has been keeping the industry busy for quite a few years. A lot of research and initiatives have gone into the question of how to best address the issue of gastric ulcers.

Determining feed particle size

Under normal circumstances, feed production sites can perform feed particle size checks using a device known as a “sieve shaker.” The method can work with both dry and wet feed samples. This method, however, is time-consuming and quite dependent on correct feed sampling. In short, it is a method that called for improvement.

Driven by the desire to reduce the incidences of particle size-induced gastric problems in pigs, Danish feed manufacturer Vestjyllands Andel, headquartered in Herning, developed a tool to tackle the issue automatically and to guarantee the required degree of grinding at factory level. The patented solution is called “VA SizeMatters” and was taken into use in 2021.

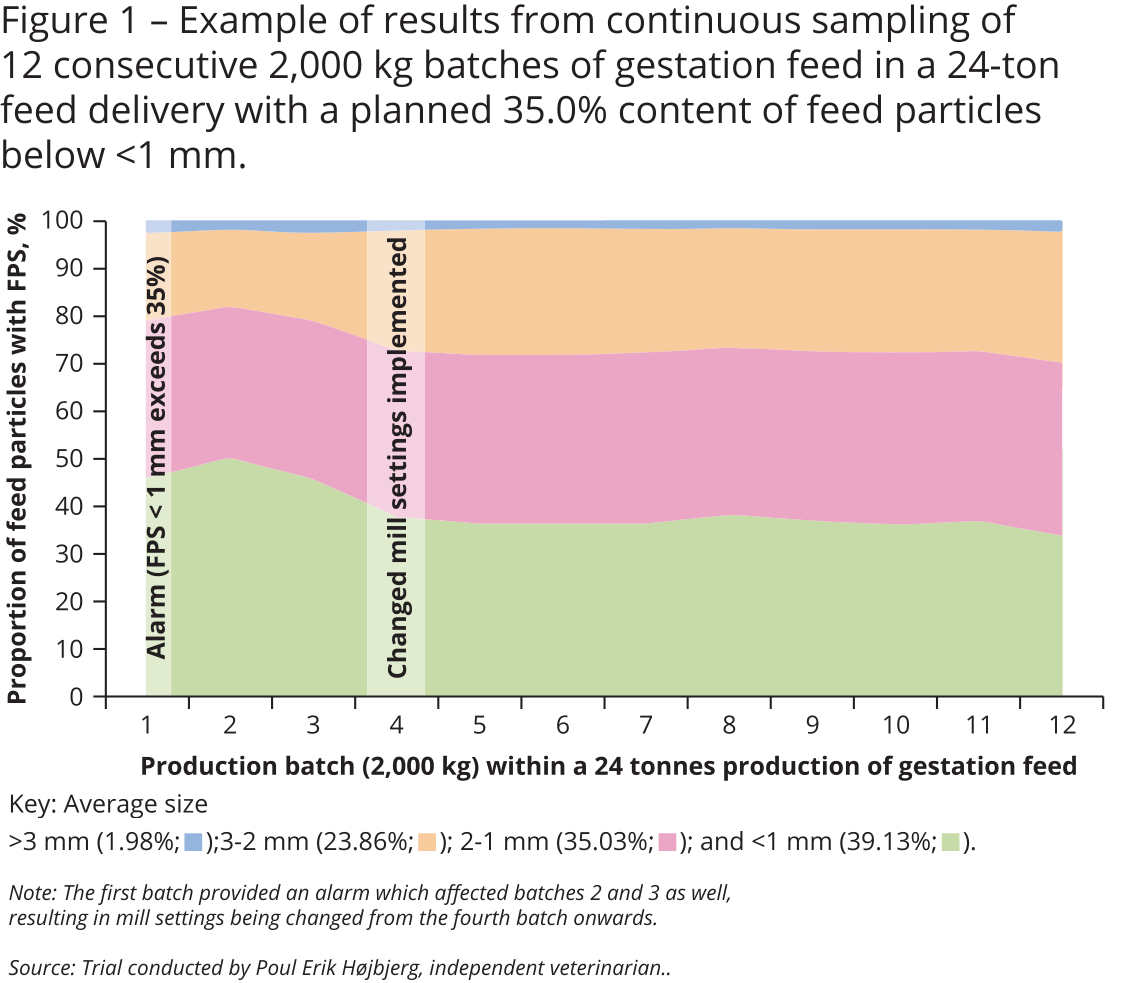

The new device works according to the principles of the “Theory of Sampling”. This means that samples are automatically sieved using screens of 3 mm, 2 mm and 1 mm. The entire process is performed during the production of the feed. This enables a check of feed particle sizes for every feed batch of 2,000 kg produced at the feed mill. The system includes software for real-time monitoring, which consists of an alarm system and documentation of batch-to-batch variation in feed particle size. In this method, the system generates an alarm when particle sizes are too coarse or too fine, and then the mill settings can be corrected by making adjustments with a delay of three batches.

Figure 1 shows results from using the method. The results are then used to adjust the feed processing to achieve a stable particle size, over time.

Focus on stomach ulcers

Stomach ulcers have also been a key focus area for Denmark’s independent research organisation SEGES Innovation. Involved in trials to study stomach ulcers is Thomas Sønderby Bruun, senior pig specialist. He has been working on such trials for a few years now, including collaborative trials on finisher pigs with Vestjyllands Andel. He confirms that normally providing pelleted feed ad lib would lead to an increased risk of stomach ulcers. With more control of particle sizes in pelleted feed, however, it proved to be possible to use ad lib pelleted feed without a higher prevalence of stomach ulcers.

The new concept appeals to him, Sønderby Bruun says. “In my opinion, this developed concept is breaking news in the feed industry. It allows instant monitoring of feed particle size and immediate adjustments to deliver feed that maximises pig feed utilisation while, at the same time, considers stomach health to avoid issues with stomach ulcers.”

Benefits in a study

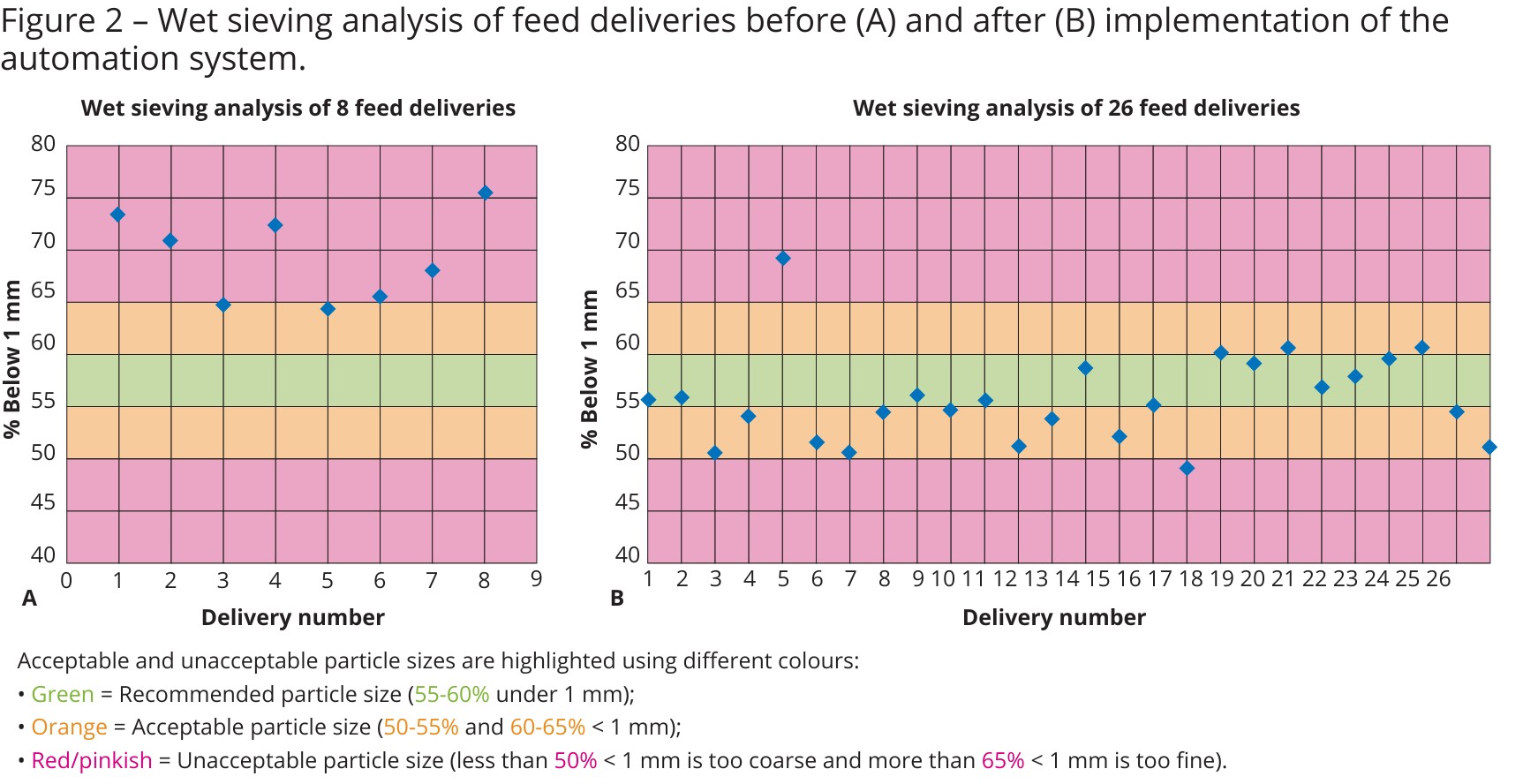

The benefits of implementing the automated sampling method were further demonstrated in a case study carried out by an independent veterinarian in 2023. In the study, the vet used a Danish herd with 1,650 sows who were struggling with gastric ulcers and increased mortality. Feed was trucked in from an external feed company. The researcher investigated eight feed deliveries for particle size distribution (see Figure 2A). Only 2 batches were within the acceptable particle size (60%–65% under 1 mm).

After providing the same sow herd with feed from Vestjyllands Andel using the automated sampling method (Figure 2B; 26 feed deliveries), virtually all batches were within the recommended and acceptable particle size (50%–65% under 1 mm, green and yellow regions).

In addition, an improvement in sow production results could be noted (see Table 1). There were improvements in weaned pigs/sow/year as well as a decrease in the sow mortality rate.

A quick look ahead

The initial focus of the VA SizeMatters development was on sows and provided more tailor-made feed for this type of pigs. The prevalence of gastric ulcers in culled sows was found to accurately reflect the occurrence of the problem in entire herds. Today, grinding profile recommendations have also been created for piglets, weaners and finishers. In addition, the company intends to focus on other animal species in the future, as well.

Looking ahead to the future, Jakob Holm Jonsson, product advisor at Vestjyllands Andel, is positive. He says, “Where particle sizes need regulation, VA SizeMatters fits in perfectly. We also have reports of Norway chicken farmers implementing it, and we see a bright future for pig farmers struggling to control stomach ulcers in pigs.”