Is feed sanitation critical to swine virus mitigation?

Feed is a crucial component of swine production, providing essential nutrients for growth and development. However, the presence of pathogens and viruses in feed poses significant risks to swine health and productivity. In recent years, heightened concerns over disease transmission, particularly from viruses like Porcine Epidemic Diarrhea Virus (PEDV) and African Swine Fever Virus (ASFV), have underscored the importance of feed sanitation in mitigating disease spread within swine populations.

Livestock feed serves as a potential vector for a wide range of pathogens, including bacterial and viral contaminants. From the farm to the feed mill, feed ingredients can harbor pathogens that threaten swine health and production. The introduction of contaminated raw materials or the improper handling and storage of feed can facilitate the spread of diseases such as PEDV and ASFV, leading to significant economic losses for swine producers. Additionally, failures on feed mill biosecurity could increase the risk of contamination of finished feeds during production.

Proactive measures to preserve feed hygiene are essential for preventing disease transmission in swine herds. Heat treatment, ingredient holding times and feed additives are among the strategies commonly employed by feed producers to mitigate the risk of pathogen contamination in feed.

Feed hygiene in preventing disease transmission

The emergence of the Porcine Epidemic Diarrhea Virus (PEDV) in North America sparked extensive research into the role of feed as a carrier for swine viruses. With mounting concerns and continued introduction of the African Swine Fever Virus (ASFV) to ASFV-negative countries, feed biosecurity has become a focal point. Both PEDV and ASFV now stand alongside a growing list of commonly monitored bacterial pathogens, including Salmonella, Listeria monocytogenes, and pathogenic Escherichia coli bacteria.

Consequently, buyers and nutritionists meticulously consider the risk of contamination when sourcing materials and formulating diets, especially important for certain ingredients such as soybean meal, which have repeatedly exhibited increased susceptibility to contamination. Pathogens such as Salmonella, as well as notifiable diseases like PEDV and ASFV, have been evidenced to infiltrate feed and its ingredients, eventually finding their way into feed mills and the supplies of farmers. Halting pathogen spread at the source is essential, as once these critical challenges are present on the farm, widespread transmission often occurs through pig-to-pig interaction. Protecting feed from contamination is not just feasible, it is a vital element in preventing herd infections.

Mitigation strategies for bacterial and viral contamination of feed often include heat treatment, extended ingredient holding times and the use of feed additives. While a 2019 review acknowledges the potential efficacy of these methods, it underscores that even when executed correctly, heat treatments and ingredient sequestration only provide protection at the time of implementation. More recent work (2024) shows that heat treatment up to 100°C may not be sufficient to mitigate viruses such as ASFV in feed, increasing producer urgency to identify effective solutions. Further research is warranted, but certain feed additives show promise as defenders of feed hygiene.

Research conducted in the wake of outbreaks like the PEDV outbreak in 2013 not only evidenced the role of feed as a potential source of viral contamination, but have demonstrated the ability of viruses like ASFV, PEDV, and Seneca-virus A (SVA) to survive and remain infectious in feed for extended periods. Additional studies have shown that consumption of contaminated feed could lead to swine infections.

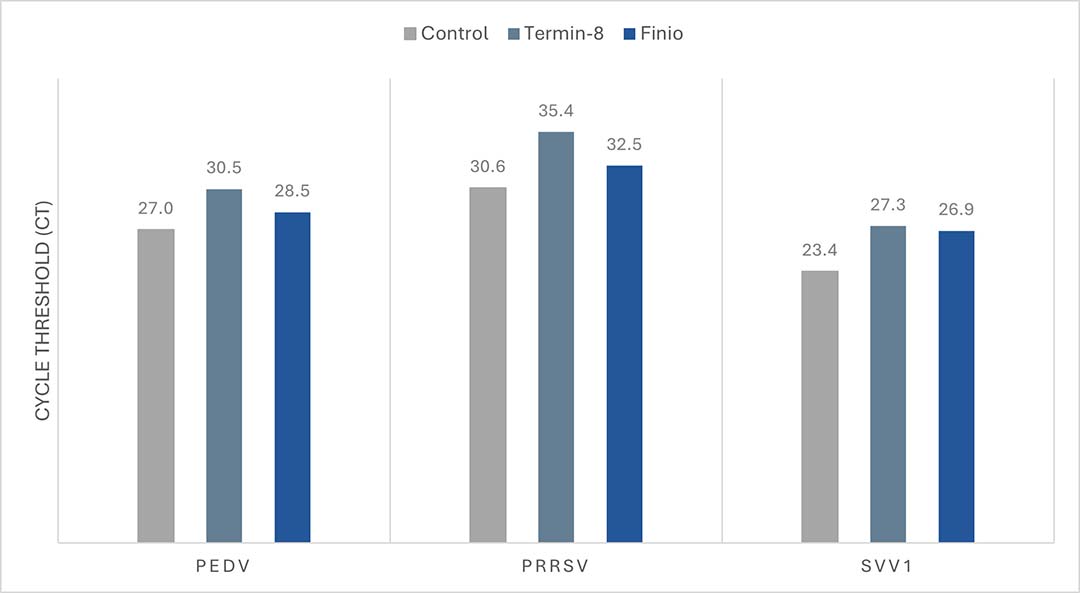

Figure 1 – Impact of feed sanitisers on viral RNA when applied post-inoculation

More recently, experiments conducted by Kansas State University found that applying feed sanitisers, Termin-8 and Finio, reduced the detectable levels of PEDV, PRRSV and Seneca Valley virus 1(SVV1) in contaminated soybean meal prior to virus contamination in feed and after virus contamination in feed (Figure 1) where increased cycle thresholds correlate to less viral RNA. (Seneca virus is sufficiently similar to ASFV and Foot and Mouth Disease to be considered a surrogate for these viruses).

Feed sanitation on swine health and productivity

Clean feed promotes growth efficiency by preventing microbiome disruption and protecting pigs from disease-causing pathogens. By controlling the microbial load from production to consumption, feed of the highest quality is provided to swine, ultimately supporting optimal growth and performance. Feed sanitisation significantly reduces the risk of disease transmission from feed to animals, contributing to improved herd health and profitability for swine producers.

Studies have shown that feed sanitisers, such as Termin-8 and Finio, can effectively reduce viral contamination in feed and improve overall animal performance by effectively mitigating feed microbial loads and support gut health. True feed sanitisers offer long-lasting recontamination protection, safeguarding feed from viral and bacterial challenges until it is fed to animals.

Feed sanitation plays a critical role in mitigating the spread of swine viruses and ensuring the health and productivity of swine herds. Effective strategies for feed hygiene, including the use of feed sanitisers, are essential components of comprehensive biosecurity programmes for swine production operations. By prioritising feed sanitation and implementing proactive measures to prevent disease transmission, swine producers can protect their herds from viral contamination and optimize pig performance.

Producers wanting to take effective action to protect their animals against contamination can get more information at www.anitox.com.