Beyond ZnO: Strategies for sustainable pig production

In the ever-evolving landscape of monogastric nutrition, few developments have been as transformative as the widespread use of zinc oxide (ZnO) in pig diets. The European pig industry is currently undergoing a significant shift – one that calls for a re-evaluation of traditional practices and a search for innovative solutions. What insights has the “post-ZnO era” yielded?

Historically, ZnO has been used in pig diets at pharmacological levels, thanks primarily to its antimicrobial properties and particularly for the role it plays in combatting post-weaning diarrhoea and promoting overall gut health. Due to these results, ZnO was seen as a linchpin in the quest for efficient pig production and disease management in the absence of antibiotic growth promoters.

However, concerns about environmental impacts, antibiotic resistance and food safety prompted the European Union to implement a ban on the use of therapeutic doses of ZnO in animal feeds in June 2022. The transition into the post-ZnO era has brought with it several challenges – but it has also presented the industry with an opportunity to develop alternative strategies that help maintain pig health, improve growth performance and reduce the post-weaning growth check. So, what has been learnt over the past 12 months?

Post-ZnO strategies: Lessons learnt

In preparation for the switch to zinc-free production, several alternatives to ZnO in piglet diets have been explored and researched over the past several years. Although each producer’s choice of alternative may depend on the specific goals of their unique pig unit – such as promoting piglet growth, maintaining gut health and preventing post-weaning diarrhoea – some dietary alternatives that have shown promise since the ban on ZnO was introduced include the following:

Probiotics

Probiotics are live micro-organisms that can boost gut health when administered in adequate amounts. Certain strains of beneficial bacteria, such as Lactobacillus and Bifidobacterium, have been used as alternatives to ZnO to promote gut health and balance the intestinal microbiota.Prebiotics

Prebiotics, such as fructo-oligosaccharides and mannan-oligosaccharides, are non-digestible substances that can be added to piglet diets to support gut health and development by promoting the growth and activity of beneficial gut bacteria.Enzymes

Enzyme supplements, such as carbohydrases and proteases, can improve nutrient utilisation in piglet diets. These enzymes break down complex carbohydrates and proteins, making nutrients more bioavailable to piglets.Organic acids

Organic acids, such as formic acid, citric acid and lactic acid, can be used as acidifiers in piglet diets. These acids work to lower the pH in the gastrointestinal tract, thereby fostering an environment that is less conducive to the growth of harmful bacteria while promoting the growth of beneficial ones.Phytogenic feed additives

Phytogenic feed additives, which are derived from plants and herbs, have been studied for the potential benefits they can provide to piglets through their diets. These additives can have antimicrobial and anti-inflammatory properties that support gut health.

Strategies and management practices

In addition to nutritional alternatives, several other strategies and management practices are available for promoting piglet health and reducing reliance on ZnO in piglet diets, including focusing on:

Weaning age: Adjusting the age at which piglets are weaned can have a significant impact on their health. Delaying weaning, when possible, provides piglets with more time to develop a mature digestive system and immune system, thereby reducing the stress associated with the transition to solid feed.

Clean environment: Maintaining a clean and hygienic living environment for piglets is essential to reduce their risk of disease. Regularly cleaning and disinfecting their pens and other equipment can help prevent the spread of pathogens.

Biosecurity: Implementing strict biosecurity measures can help prevent the introduction of diseases onto the pig farm. This includes controlling access to the facility, ensuring that all visitors follow the proper protocols and monitoring the health of incoming animals.

It is important to note that the effectiveness of these solutions and management practices can vary depending on each individual’s farm circumstances, such as the weaning age, the genetics used, the environmental conditions and the presence of specific pathogens, meaning that there is no one-size-fits-all solution.

And while there have been successful transitions to ZnO-free piglet production, not all pig units have been able to go without ZnO and subsequently continue to face several challenges. Across Europe, some pig producers that relied heavily on ZnO as a growth promoter or to manage post-weaning diarrhoea have reportedly struggled to find a suitable replacement that provides consistent results, and the piglets on these farms are continuing to experience health issues, leading to increased mortality and lower growth rates. In other incidents, despite producers implementing strict biosecurity measures and vaccination programs, some farms have still experienced disease outbreaks, as the absence of ZnO – which offered some protections against certain pathogens – made piglets more susceptible to infections. As a result, this has not only reduced pig performance but led to an increase in antibiotic use and additional veterinary costs.

Alltech technologies and solutions

The ongoing challenges faced by pig producers as they move to zinc-free feeding highlights the complexity of such transitions and the need for further research into natural alternatives to ZnO. At Alltech, we believe that the journey towards zero ZnO begins in the gut. Over the past 40+ years, Alltech has conducted extensive research studying monogastric gut health and has designed several gut-health management programmes that focus on supporting animal performance from birth.

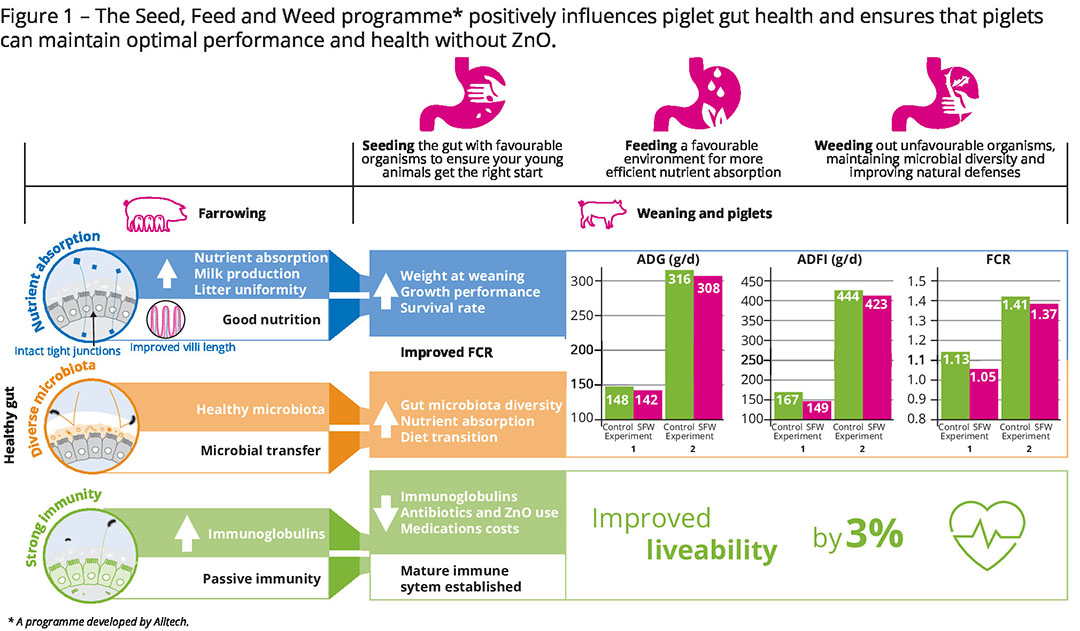

Incorporated into these programmes are natural feed materials, such as those included in Alltech’s Seed, Feed, Weed (SFW) programme, which is designed to promote favourable microbial communities in the gut, optimise gut structures and support the immune system to positively impact the growth and health of young piglets (see Figure 1).

Conclusion

Several alternatives to ZnO have demonstrated their efficacy in promoting piglet health and reducing the incidence of post-weaning diarrhoea. However, it’s important to note that a combination of these strategies – as well as tailoring the approach to the specific needs and challenges of each pig farm – is often necessary to maintain piglet health and performance and to reduce the need for ZnO or antibiotics in piglet diets. Staying updated on the latest research and industry best practices is also important for ensuring that piglet management continues to improve.