Farm-specific diets (part 2)

Last month I described what FSDs were and provided some of the performance improvements over what many do now – which is to buy ready-made diets from the feed compounders’ range at the best price the producer can negotiate.

The FSD concept, using information from you on your own farm conditions, allows the same nutritionist to design grow-out diets specifically for your on-farm conditions and not rely on the usual three starter/ grower/ finisher diets (sometimes as many as seven) which have always had to be something of a compromise. The FSD concept will bring – is bringing – about a major change in the way we buy growing/ finishing feeds, as the diets will be designed to match your on-farm conditions and thus the price per tonne will become far less critical. I will deal with the econometrics in the next article.

Different

We’ve always known that each pig farm is different, but how very different they can be has come to the fore over the past eight years. I list a few of the more important on-farm differences that I recorded – these differences can be as high as 15-20% in some cases.

• Difference between three contracts for the same weight range of pigs;

• Variation in daily liveweight gain;

• Variation in VFI (appetite) between four breeds/genetic lines;

• Variation in growth characteristics within a single genotype;

• Performance differences on the same diet under the same environmental conditions.

Nutritional design

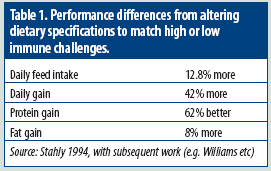

In order to provide the best nutritional design to the grower pigs, it would be good to provide them feed that matches their individual immune status. An example from 1994 (Table 1) clearly shows what differences can be achieved this way.In parallel with this rather sobering information have come changes in raw materials and price, and advanced knowledge of how the growing pig uses both familiar and alternative feed ingredients, plus major advances in genetic lines from the breeding companies. Put these four variables together and you have a situation which demands a new approach. We have all heard of ‘precise nutrition’. Today it has become ‘super-precise’ – providing the producer supplies the farm details needed to make it work.

What information does the pig nutritionist need from you?It is really quite simple and not onerous to provide. A bit more measuring, time and discipline which – sure – costs extra, and the additional work the nutritionist and the feed mill contribute adds to this as well. But so far the benefit paybacks have ranged from 2:1 to as much as 12:1, with an expected mean of around 6:1.

1. The weight of pigs entering a department.

2. The weight of pigs leaving the department.

3. The time spent in the department – thus the daily gain.

4. The amount of food they ate (the nutritionist may ask about a rough feed wastage estimate).

5. From the geneticist direct to the nutritionist, a statement of what they should be capable of (predicted growth curves). You only need to inform the nutritionist if the genetics are to be changed – to which line, AI supplier or breeding company.

6. What marketing constraints are in the contract, this too should it ever change materially.From time to time if he notices a fall-off in performance the nutritionist may ask other questions – about stocking density, temperature or health, for example. At least you will know that someone is keeping an eye on things and that he/ she might be able to mitigate it while you address the problem.

Weighing a worry?

Producers examining this list may be worried about the weighing aspect. Don’t be. No need to weigh everything unless you want to. Where pigs are concerned, some nutritionists are content with input and output weights as in 1 and 2 above, sent in by e-mail every three to four months. Others advise selecting what you consider to be typical examples from two or three pens (30 to 50 pigs) and weighing them every three to four weeks and sending that in by e-mail. The workload is reduced if a group weigher is used as the whole pen weight is sufficient, providing if it is the same pen each time and any culls/ deaths reported. For the ‘few pens’ system it is important to estimate feed wastage, needing keen observation. Even so, not rocket science, is it!

Next month: Some more tips and observations.