Creating more power underneath the pig house

Over the last couple of years, pig manure has had a tendency to become less fluid. This means that discharging any manure system has become increasingly tough as well. Solutions are at hand.

By John van Schriek, Jovas Agro International, ‘s-Heerenberg, the Netherlands

©

The amount of dry matter in pig manure has increased tremendously over the last ten years. In Eastern Europe, for instance, dry matter quantity used to be about 1-2% a couple of years ago. Nowadays, however, dry matter content may be as high as 6-10%.

©

©

There are several reasons why the quantity of water in pig excrement has been reduced severely over this period of time. Pig houses are built with increasingly smooth materials, hence cleaning takes less water. In addition, the quality of water nipples and/or water reservoirs has been improved significantly, reducing the amounts of water in manure as well. Thirdly, there have been increasing amounts of welfare requirements in relation to the presence of compound feed or welfare feed.

©

Using less water translates into a positive development for pig producers, as transporting costs for manure go down. Less amounts of water need be transported to the fields or a biogas installation. The downside of these developments, however, is that pig manure is increasingly difficult to get out of the manure pits. Improvements in sewer systems simply could not keep up with the pace of development of pig house sizes.

©

One of the solutions suggested is to equip pig houses with a deeper sewer system. This causes an increased amount of pressure on the valves, hence more storage capacity and more manure velocity. Expensive as this solution is, however, often it is also impossible to create a manure pit deeper than 4 m into the ground.

©

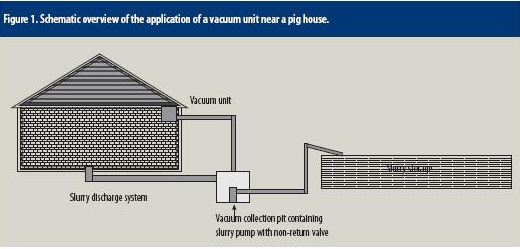

Forced vacuum system

A forced vacuum system has been developed to deal with the increasing amount of problems. By adjusting a vacuum pump to the sewer, low pressure can be applied, see Figure 1. By having a low pressure of approximately 1 metre, both liquid and solid manure will float away more quickly. In November last year, first practical tests were conducted and they looked promising. In some cases, manure levels were still as high as the slats in manure pits of 25 metres length. Using a vacuum system, this was significantly reduced to a level of about 5 cm.

©

Conventional manure discharge systems can be divided into two groups – one with a plug in the drain and one with a central lock having various drains. In both systems, a vacuum system can improve their performance.

©

One plug drain

When no vacuum system is used, a one-plug drain can cause some side-effects. Generally, when having large diameter drains (e.g. 315 mm), toxic air can be floating back into the pig house, which can lead to an increased mortality in the herd.

©

In addition, when pig farms grow larger, and an on-site mix-and-mill installation is being used, the quantity of proteins in feed is often too high. For the animals, this is not damaging, however, this contributes to the creation of toxic gases – and this problem may only increase in the near future. Creating a low pressure in the manure pit, however, would prevent the occurrence of such a problem.

©

©

More than one inlet

In systems, having more than one inlet, problems related to toxic airs floating back into the pig house are virtually non-existent, as the diameters are too small for that. With the ever increasing amount of pig houses, in conventional discharge systems, more than one inlet can be created at one sewer branch to the main manure pit. The optimum would be four inlets, having a maximum distance of 5 m (see Figure 2). The first inlet – which is smaller than the underlying drain – will attract 70% of the manure, the second will take approximately 15%, the third 10% and the fourth 5%. The next inlets usually do not attract any manure. Having low velocity in these pipes, the sediment will obstruct the sewer system, leading to a blockage in various years.

©

A vacuum system, however, will increase the manure’s speed and will make sure even the fifth inlet will attract manure. In addition, the manure’s velocity in the main manure pit will be increased, which is why the manure will not decompose in solid and liquid fractions.

©

In this last system, including floating balls on top of each inlet may even step up the efficacy of this idea. In case the area around the first inlet has almost been emptied, a ball will block the inlet. This will step up the quantity of attracted manure to 70% at the second inlet, and improve the quantity at the third inlet to 15% etc. PP

©

To learn more about an on-farm application of this manure system, turn to www.pigprogress.net and visit the video section.

©

Source: Pig Progress magazine 25.10