Optimised heating consumption and improved minimum ventilation

Dynamic Air is a new ventilation principle that ensures the producer improved minimum ventilation as well as optimised heating consumption.

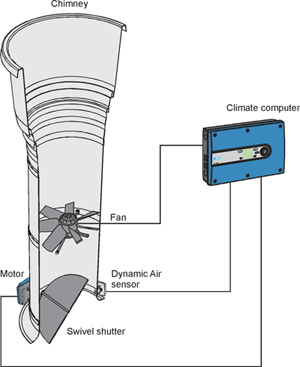

Dynamic Air (patent pending) is a new principle for online measuring of air output in air outlets.

“We place a Dynamic Air sensor by the flap in the air outlet, so that the climate computer can calculate the airflow in the exhaust unit with complete accuracy,” said Michael Tækker, Farm Application Specialist, SKOV A/S.

High animal welfare – low heating costs

An accurate measurement of the output is particularly important in connection with minimum ventilation. Correct

minimum ventilation is crucial to productivity and heating costs. A too low degree of ventilation affects the welfare of the animals and productivity. A too high degree of ventilation, on the other hand, means unnecessarily high heating costs.

“By way of example, we recommend minimum ventilation of 3 m3/h/pig when weaners of 7-30 kg are stocked in two-climate pens with air jet ventilation. If the minimum ventilation is in fact 5 m3/h/weaner at the time of stocking rather than the recommended 3 m3/h/weaner, energy consumption will increase from 50 to 78 kWh/pen place/year. In other words, minimum ventilation has a great effect on the heating costs,” Michael Tækker continued.

Areas with severe wind impact

Heavy winds have always been minimum ventilation’s number one enemy. Strong winds make it difficult to maintain sufficient and constant minimum ventilation. The problem has been resolved by running the fan at a high number of revolutions and then regulating the ventilation level by means of flap opening.

“The Dynamic Air measurements constantly make allowances for any pressure drop that may occur because the exhaust unit is exposed to too great wind impacts, and therefore the fan can be adjusted closer to the actual need,” Michael Tækker added.

No mechanical weaknesses

Today, a mechanical fan whell anemometer is the most common technique used to determine airflow. However, a fan whell anemometer causes some resistance in the exhaust unit, which reduces the output of the unit.

“A fan whell anemometer is also a mechanical construction located in a ‘hard environment’ directly inside the exhaust unit. Over time, the fan whell anemometer will measure less accurately because of wear, and in the worst-case scenario, it will break. The direct contact between the measuring equipment, as seen in the case of the fan whell anemometer, is non-existent in Dynamic Air, and consequently, the risk of wear and breakdown is minimised,” Michael Tækker concluded.

Overall, the Dynamic Air concept offers a very precise determination of airflow without any use of mechanical, movable components, which makes it reliable and financially attractive and gives it long-term stability.