Getting a better grip on internal biosecurity

![How to know exactly how much detergent and disinfectant to use between batches of pigs? [Photo: Cid Lines]](https://www.pigprogress.net/app/uploads/2021/04/001_595_rb-image-2691525-848x565.jpeg)

Many textbooks touch on the topic of external ?biosecurity, i.e. how to keep pathogens out of a farm. Making it difficult for pathogens to spread inside a pig house is a different ball game ?altogether. With the right data and knowledge, a precise internal biosecurity is possible.

The importance of biosecurity has been stressed in many scientific articles, farm reports and articles in this and other publications. It is important to discern between external and internal biosecurity.

Handling external biosecurity deals with the strategy of keeping infectious diseases away from farms. It is a topic many of the aforementioned publications try to supply answers to – and is hence not the focus of this article.

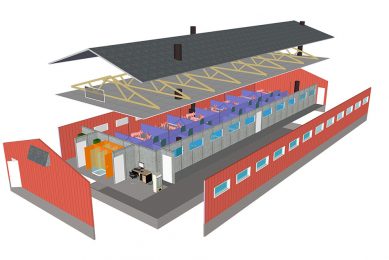

Internal biosecurity, however, revolves around the question how to prevent the spread of contagious diseases within the farm. Is this from pen to pen, from unit to unit or from house to house? Whichever strategy is chosen, cleaning and disinfection procedures play a major role in internal biosecurity and more particularly in the prevention of disease propagation from one group of animals to the next, growing up in the same pen or house.

Cleaning & disinfection procedures are applied by pig farmers all over the world, in both developed and developing countries. Often, however, they are based on historically grown routines, shaped over years rather than being based on well-considered protocols. Frequently, practices like these have led to sub-optimal technical results. Creating doubts as to whether the money spent on these protocols contribute to the farm’s zootechnical and financial health status. Indeed, several crises in the industry have often led to cost-cutting measures related to these, whereas a well-designed plan for smart and consistent biosecurity, executed flawlessly, is nevertheless a cornerstone of good biosecurity practices.

Precision management

Zooming in a little bit more on internal biosecurity, cleaning and disinfection is a job that requires precision, balance and understanding – several examples can explain why.

The environment is among the examples to consider. Originating from fear of not applying enough chemicals, some farmers have developed a somewhat twisted belief that can be described as ‘more is better’. The truth is, however, that overconsumption of chemicals and water leads to unnecessary environmental pressure, without resulting in an improved control of the transfer of pathogens.

Equipment is another reason to think of. Many pig producers overlook the effect of (over)consumption of chemicals on farm equipment (like feeders, farrowing crates). Sometimes people are tempted to use inappropriate or low quality detergents in an attempt to save money, with damaged installations as a result. The excessive wear and tear of the equipment does not necessarily appears after a single application but shows up only after repeated application.

The workforce is a third reason to keep in mind when deciding on a cleaning and disinfection strategy. Perhaps less obvious at first, but on-farm staff are a mobile international force. They are the ones that use the cleaners and disinfectants. Providing clear instructions in their language will evolve into a better execution of the tailor-made protocols.

Safe use of farm cleaners and biocides

These examples show that there is a need for clarity and precision – hence they have been right at the heart of the development of Cid Lines’ Prevention Cost Calculator. After all, an ideal management practice manual developed for pig farms would have to require a detailed sanitation plan including full cleaning and disinfection for each room or building between the departure of one group and the introduction of the next. Essential in this manual would be the pre-calculation of exact quantities of chemicals needed per room, as this leads to a more precise consumption of cleaning and disinfecting products. When provided in various languages, detailed instructions will enable your (external) labour force to move from room to room.

In the end, this benefits the environment, equipment, workforce, animals and the pork producer. See the box for an explanation of how this new app can help you.

Smartphone app assisting pig farmers

Cid Lines’s new tablet and smartphone app Prevention Cost Calculator has been developed to assist pork producers in how to make the right management decisions for their sanitation protocols.

Above all, the app serves as a calculation tool. On the basis of farm data it will give a perfect insight into the volume of detergent and disinfectant needed for a personalised hygiene protocol. The advice will be based on parameters linked to the size of the pen as well as management data like downtime and stocking density. The calculation method is based on scientific studies as well as field experience of Cid Lines technical specialists.

Apart from a calculation tool, the app also serves as a budgeting tool. It allows pork producers to estimate very precisely the total amount of detergents and disinfectants needed per cycle per year or per animal sold.

The app is available for iOS and Android.