Biogenic amines in pig liquid feed: Myth or reality?

Do biogenic amines exist in liquid pig feed? Most certainly they do – and not only there. After consumption, they pass through the gut into the animal’s blood, representing a true hidden hazard for pig health and performance. What exactly are these biogenic amines and what are the main risk factors?

Biogenic amines are non-volatile amines, released by the decarboxylation of amino acids by bacterial enzymes (decarboxylases). In practice, they are toxic compounds produced during the putrefaction of easily degradable feed and food (like meat, fish and sea shells). They are principally produced by bacteria such as enterobacteria or coliforms. In humans, the toxicity of certain of these compounds is well described and they are routinely assessed in food (e.g. in seashells). For example, the presence of histamine in food above 50 ppm leads to the onset of symptoms like a rash or itching. They even worsen strongly by 100 ppm, leading to headaches, anorexia, nausea or asthma. Between 400-1,000 ppm, vasodilatation and anaphylactic shock can lead to heart-lung decompensation and at levels over 1,500 ppm histamine can be lethal.

Animals

In animals, it has been shown that a microflora disequilibrium in the bovine rumen or the equine hindgut can lead to increased histamine production which has been linked to the onset of laminitis. And what about pigs? They are certainly sensitive to biogenic amines too and if those have little chance to develop in dry feed, they could potentially represent a hidden hazard in liquid feed. What are the risk factors for biogenic amines development in liquid feed? How to assess the quality of liquid feed with regard to biogenic amines and finally what is their impact on pig performance and health? Little is known about the presence and significance of biogenic amines in pig liquid feed and their toxicity in pigs.

Nevertheless, some cases of laminitis have been described in sow fed liquid by-products. In Belgium, sudden death cases in fattening pigs have been linked to pea cream fermentation. Moreover, in 2007, 2 other studies led by Prof Peter Brooks and Dr Nuria Canibe, reported high levels of biogenic amines in liquid feed in farms which experienced decreased feed intake and performance as well as increased severity and frequency of diarrhoea during the pigs’ transition to liquid feed. In order to get a better picture of the situation of biogenic amines in pig liquid feed, and their impact on pig performance and health, Lallemand Animal Nutrition set up a large-scale survey involving 33 commercial pig farms in France. Several questions were key:

• Is biogenic amine contamination a reality in the field and what is the prevalence?

• What are the main biogenic amines in liquid feed?

• Do these eventual biogenic amines reach the systemic circulation?

• Can we identify risk factors, likely associated with biogenic amines and can we suggest preventive measures?

The survey

The survey was conducted in two steps, between 2009-2010. All farms tested (33) used liquid feed in fattening pigs, either complete feed from a feed mill (9 farms) or home mixing farms split as such:

• 18 used wet corn or high moisture

corn with a ‘prefermentation’ step

• 3 used dry grains

• 3 used liquid by-products.

The raw materials, like corn or byproducts as well as the liquid feed at each step (mixing/ or prefermentation tank; distribution pipes after a few hours in the system; in the troughs and ‘leftover’ tank) were sampled for bacteriological and biochemical analysis. 10 biogenic amines were measured by HPLC: putrescine, tyramine, cadaverine, serotonine, histamine, agmatine, beta phenyl ethylamine, spermidine, tryptamine, spermine. In addition, a bacteriological analysis comprised both positive (lactobacilli, the acidifying microflora) and negative (enterobacteria, coliforms) microflora. The blood of certain random pigs was sampled at various steps: postweaning, when still fed dry feed; as well as several time points during fattening. All blood was then tested for the ten biogenic amines. The pigs’ faeces were also analysed at same time points to evaluate the level of biogenic amines in the digestive tract.

A true threat

The average biogenic amines values for each feed type are reported in Table 1 (feed sampled in the trough). The first striking evidence of this survey is that if it confirms the presence of biogenic amines contamination in liquid feed, sometimes at very high levels, it also shows a huge farm-tofarm variability. Furthermore, the farms with high levels of contamination were resampled one to two months after the first analysis: the results were comparable, leading to a conclusion that biogenic amine contamination is a characteristic linked to the farm. Other conclusions, to be drawn from Table 1, are that farms using complete feed from a feed mill show more homogenous and lower contamination levels compared to home mixers; and that by-products and wet corn appear to be important risk factors. Moreover, the level of biogenic amine contamination in distribution pipes or leftover tanks is on average 5.3 times higher than in mixing tanks on the same farm. All these observations confirm the role of uncontrolled bacterial fermentation on biogenic amine production: in the leftover tank, but also along the distribution pipes where a biofilm is most likely to line the surface, leading to continuous fermentation and biogenic amine release along the circuit. In the case of wet corn, which shows the highest contamination levels, it should be remembered that this type of feed is subject to three successive fermentation steps: after harvest (ensiling); during feed preparation (prefermentation) and in the final feed.

Variability

Looking at the ten individual compounds some variability and overall tendencies can be seen. Whichever the level of contamination and feed type, the survey showed that the same biogenic amines were always predominant: tyramine (from tyrosine, the most abundant amino acid in vegetal proteins); cadaverine (from lysine); putrescine (from arginine); histamine (from histidine). Based on the three first biogenic amines, a predictive model of the overall contamination level was designed:

[biogenic animes]total= 58.05 + 2.02*

[putrescine] + [cadaverine] + [tyramine].

This model could lead to potential cost savings when doing an analysis. In parallel, the feed bacteriological analysis (Table 2) also shows great farm-to-farm variability. These data show the importance of coliforms and enterobacteria contamination at several steps: The raw material (the crop or by-product), feed, but also in the distribution network due to the bacteria present in the biofilm. According to Dr Jane Beal, Plymouth University, UK, one of the key criteria to define the quality of liquid feed is the predominance of lactic acid bacterias (LABs). They are responsible for the fermentation of sugars from the feed into lactic acid: a concentration of lactic acid >150 mmol/l of feed is a good indicator of a well acidified, well preserved liquid feed. Many micro-organisms, and in particular pathogens, do not grow when the pH<4.

From feed to pig

The pig blood analysis (Tables 3 and 4) confirms the passage of certain biogenic amines (putrescine, spermidine, spermin) into the systemic circulation. It was observed that after the transition from dry to liquid feed, the biogenic amine levels in blood on average doubled. This could indicate that the biogenic amines from the liquid feed were transferred into the blood flow through the gut. When looking at faeces contamination however, these are higher in post-weaning piglets, even though serum levels are low. This could be easily explained by the fact that piglet feed has very high protein contents (hence more amino acid degradation in the hindgut). Interestingly, the two farms where the piglets showed the highest biogenic amines serum levels (histamine in particular) were also the farms which experienced important post-weaning diarrhoeas, indicating a negative effect on pig health.

As serum contamination levels seemed rather steady during the finishing period, however, there may not have been biogenic amine accumulation in the body during finishing. Nevertheless, the half-life of the various biogenic amines and their detoxification and absorption rates are not known, so these results remain difficult to interpret.

How to prevent ‘bad’ fermentations?

As explained earlier and observed in this study, biogenic amine contamination is linked to certain ‘bad’ bacterial fermentations in the feed. Many studies on fermented liquid feed, in particular by Prof Peter Brooks, have proven the benefit of controlled fermentation on feed contamination. Controlled fermentation is based on the inoculation of liquid feed with an appropriate culture of lactic acid bacteria which will rapidly produce important levels of lactic acid, which could be described as ‘good fermentation’. The rapid acidification of the feed will limit the development of detrimental bacteria, in particular E. coli, which appear to be responsible for the degradation of synthetic lysine into cadaverin. Uncontrolled fermentation, on the other hand, is a method of preparation in which the feed is allowed to ferment and in which the LAB populations, naturally present in grains, will grow. But this source of LAB is very variable, depending on harvest conditions, etc.

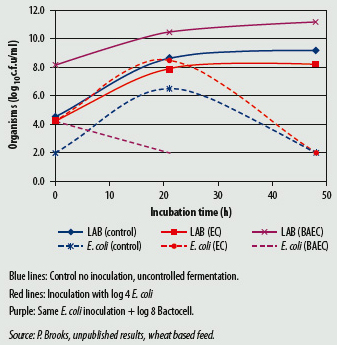

Figure 1 – Effect of Pedioccoccus acidilactici MA 18/5M (Bactocell) inoculation on coliform development in fermented liquid feed.

In addition, the acidifying process is not so rapid, leaving more ‘space’ for bad fermentations. Beal reported that uncontrolled fermentation leads to around 25% loss of synthetic lysine, while a controlled fermentation reduces this loss to under 4%. The bacteria Pedioccoccus acidilactici MA 18/5M, which is authorised in Europe in finishing pigs (Bactocell, Lallemand Animal Nutrition) is well described for its ability to produce rapidly important amount of lactic acid in liquid feed. Figure 1 shows that during uncontrolled fermentation, coliforms grow in the first 24 hours, then start decreasing as natural LAB population probably reach inhibitory levels, while controlled fermentation with this strain of P. acidilactici prevents early development of E. coli in the feed. In parallel, field results (see Table 5 for recent trials) proved that, by controlling feed fermentation with this strain of P. acidilactici, average daily weight gain (ADWG) and survival were improved. This confirms in the practice a positive impact of the controlled fermentation on the quality and potentially the safety of the feed. It has been observed under field conditions that the use of this strain brought down the level of biogenic amine contamination in less than two weeks on highly contaminated farms. It also improved feed intake, reduced digestive problems, e.g. diarrhoeas as well as mortality. Essential to say is that it all had to happen in combination with thorough disinfection and cleaning of the equipment.

References available on request. This study was presented in December 2011 at the Annual Congress of the French Swine Veterinarians Association and was awarded the Patrick Pommier Short Communication First Prize by a jury of over 100 swine vets.